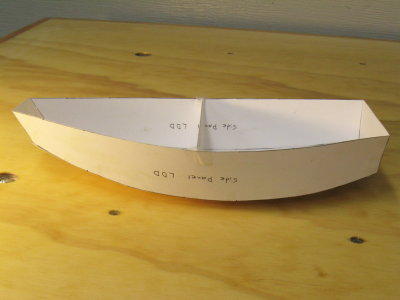

Cardstock model from scale versions of stitch and glue panels. |

Stem oblique; design based on DinkyDink, Lewis Boat Works. |

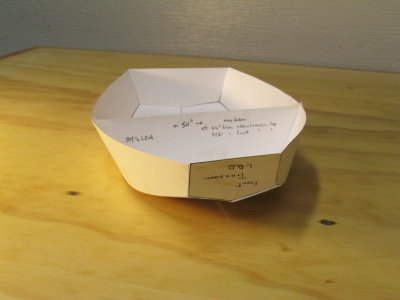

Stern oblique view. |

Model glued to reference-lined vellum. |

Stations every inch at 1:8 scale makes for 10 slices. |

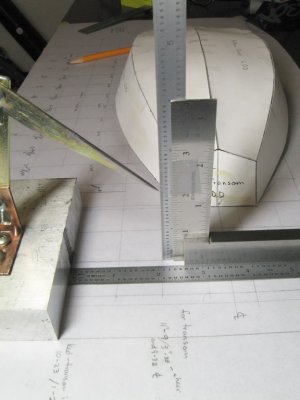

Extracting height and offset measurements. |

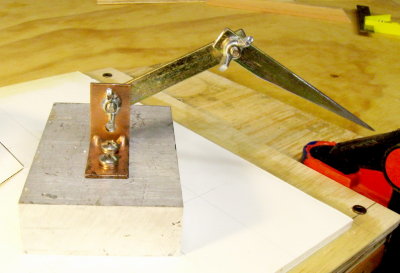

Homemade tool articulates for horizontal and vertical measurements. Ugly. It works. |

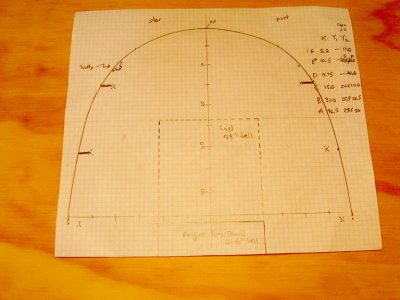

Scale plan view of Bartender cockpit; coaming line dictates tender cross section. |

Lofting: Offset and height data at each station are transferred to a grid on plywood. |

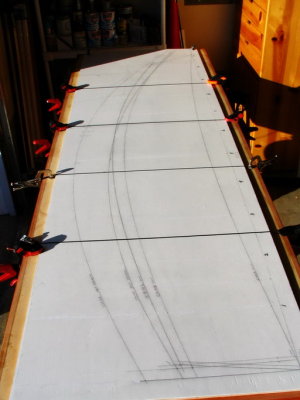

A line is drawn following the batten, visible at ends of props. Batten establishes best fit, a "fair line." |

Previous line was chine height. This is sheer half breadth. |

Close view. |

Completed lines at stern; plywood is 30 inches across. Rear transom line will define intersections. |

Height reference line connects sheer ends. Keel line references half breadths. |

At the bow, the lines cross, making measurement extraction tricky. |

Original station lines erased, to bring out frame locations. Third one from stern defines the nesting bow. |

Building surface. Cross bars at frame locations, square and true. Transom supports TBA. |

Ends of cross bars level all ways, sized for individual frame widths. |

Leg anchor -- blue screws fix each leg to the concrete. Really solid. |

On to frames. Pretty skimpy -- hoping these will be herky enough to survive paneling. |

Corners are gusseted with quarter inch plywood, here a chine. |

Frames are glued up on the body plan; each the right bit long to establish the sheer, later. |

Forward transom in position, during clampup of backing for attaching plywood. |

Rear transom, same stage. |

Frame C is a double, to separate the halves, here receiving backing for attachment bolts. |

Backing is some thin hardwood, glued on -- eight bolts, all told. |

Detail of carriage bolt attachment; collars are stainless from McMaster-Carr. |

Both transoms and two frames were pre-beveled using info from the lofting surface. |

This series shows the forward transom, with some added wood in the first photo, here beveled on each end. |

Down a little further. |

Top view. Next shot shows the completed bevel in profile. |

This is a rolling bevel, with a greater angle at the keel than the chine. Most bevels were simpler. |

All the frames up except the double, C. |

Frame C gets some backing for screws, in glue-up phase. |

Rear half of C gets some added wood to accomodate the bevel. |

Extra wood is now glued on. |

And here, beveled close to fair, on the bottom. Sides also required some added wood. |

Starboard frames faired on their flanks, looking aft. |

Looking forward; very gratifying to see all those bevels come in. |

Frames can be detached and reattached reproducibly to building surface, facilitating notching. |

Screws are #10 self-piercing sheeters, with rubber-backed washers. Very handy. |

Time to cut notches for chine logs and keelson, here the starboard chine area, double frame in the center. |

Aft end, fully notched. |

Keelson glue-up, in two layers. Full thickness too stiff to bend on without depressing frames. |

Added support between frames B and C, to keep keelson fair. |

Couple of failed efforts to bend on the chines lead to wetting the wood and gradually developing the bend. |

Easing the wood in over half an hour gave no failures; mega clamps the key, some weighted to rotate the piece into place. |

Chine logs and keelson completed, aft portion. An airy framework. |

Forward starboad chine log, first lamination: lots of twist and a captured notch in the transom. |

Fairing: excess wood over a frame is filed away to establish the correct bevel. The logs and the keelson are planed fair. |

Looks good, except to either side of the double frame; not enough curvature there. |

Reason: should have sprung the stringers through the double frame; wood being added. |

Now the chines are fair on either side of the double frame. Ditto keelson. |

Note almost a quarter inch of wood was needed between frames C and D in the center to correct the line. |

Starboard panel in place, held in position with plastic washers while the epoxy cures. |

Bronze screws through plastic medallions. Four mm okume too thin for proper screw installation. |

Most are 3/4 inch number 8's, and demand careful tightening; these are guide screws, a bit longer. |

Rapid Dave sets screws on a bottom panel. |

Clamp fiend at work. |

Bow portion of the starboard bottom. |

Stern, also in glue up. |

Mega clamps, for buddy Ralph, who really likes clamps. |

Last panel, in dry fit. |

Edges masked, to reduce remnant squeezeout. When cured, it is a bear to remove. |

Filled, faired, and ready to glass. |

Oblique view; masking identifies sheer line, eases removing excess glass at green stage of curing. |

Bottom glassed; port side glass taped in place, ready for layup. |

After layup and spreading resin but before removal of masking ... to be done mid-cure. |

Starboard sheer in clampup. Hull glass has been filled with 2 coats of resin. |

Bungie assist on the forward end of the star sheer. Eases the clamp up. |

Port sheer, installed. A deliberate, careful task. |

Bungies help pull in the sheer ends, for good control in glue-up. |

80-grit sanded overall |

Off the jig. Tabs at ends will come off and then it goes back on the jig. |

Sheer guard sections on transoms needed, yet. 65 pounds, as is. |

Time to slice the hull, here using the saw to pre-clean the kerf slot of shim material. |

Cutting from the outside, halfway across the sheer a loud pop gave this. |

The port sheer also cracked when hit with the saw, even though clamped tightly. Time to regroup. |

Glue up of the split section; white plastic covers the cut area. |

Second attempt, after glassing the sheer to the hull ply. Saw cut from the inside this time. |

Pulling across the center of the hull. |

And down the opposite chine; seam wedged to maintain an open kerf. |

End of the line; note glass reinforcement and clamped plastic keeper. No splits this time! |

Separated halves. |

Mating half-frames. |

Overall view; yes, they do re-mate when the bolts are installed! |

First nesting; frame stubs will go away soon. |

Frame stubs removed; profile view. Can you spot the seam? |

Overhead view. Sheer rail needs glass. |

Separated and upright for fiberglassing the sheer rails. A fun job. |

Saturation coat of resin on the eight Meranti plywood corner braces. |

Corner braces installed; last set in glueup. |

Springback of hull mandated serious clamping pressure to fully mate the halves. |

Oblique view. |

Port side profile view. |

Starboard side clamps. Springback made for a quarter inch gap at the rails before clamps applied. |

Fillet detail. |

Two coats of resin, aft section. |

Perspective view; lotta sanding coming up. |

Mockup of skeg, in slot, to fine tune the mating to hull. |

Mahogany skeg, held in alignment for dry fit. Screwed in place from the keelson. |

Combined glue job to the hull with glass over the fillet and up the sides. |

Same stage; alternate view. Glass gets cut off at the green stage of the resin ... |

As here, and the fillet area is cleaned up, in preparation for ... |

Application of biaxial tape along the edge. |

After wet out with resin, and again trimmed at the green stage. |

One fill coat of resin, after cleanup and fairing of tape edges. |

Thwart mockup in the aft position, for solo rowing. Shorter legs take over for tandem rowing ... |

Shown here, in an end-on view. Oarlocks here are about right for two passengers. |

Solo position |

Tandem position; couple bags of sand simulate aft loading for the second passenger -- a bit light, though, |

Sand bags, alone. Getting out of this thing will be tricky! |

Forward seat/thwart completed, |

Close-up; separates for ease in painting. In use, forward part could extend farther when two are aboard. |

Mockup of rear seat/thwart; testing on the lake showed the lowest height is best (this is highest). |

Halves nested; view from the center frames. Black material is gasket to cushion halves. |

Halves nested; view from the transoms. Note spacer separating halves. |

Side view of transoms. Spacer will be replaced with ply glued to inner half, and some chafe protection. |

Side view of inner half butting against seat/thwart of outer; bolts under seat will hold halves in place. |

Other contact is at sheer and will require some more quarter inch neoprne. |

Roughed in the rear thwart. This is the seating surface -- glueup of edge reinforcement. |

Cleats in place, fresh glueup. |

Drywall screw/plastic washer combos hold cleats in place while resin cures. |

In place; ring bolts secure forward edge; top cleat will secure it aft. |

Painted and outfitted in nesting mode: blue hull; light gray interior with bright rowing stations and rear thwart. |

Nesting achieved by bolting the center frame of one half to the rowing station support of the other. |

Bungie to ring bolts (see next photo) across bow rails. Neoprene chafe/padding at contact areas. |

And now eight bolts join halves to make a dinghy; oars in position for tandem use. |

View from the bow. |

Oar leather made from neoprene gasket material, stitched on; my first! |

The Duck nesting over the engine box, aboard Surf Scoter. |

Looking aft; needs tie-down points each side. Ideas? |

Tilted back to allow the engine box to open. |

Stepping over to the dinghy; not bad at all. |

At the catch -- good trim. |

End of the power phase of a stroke -- note the bow digging in. |

Boy, this thing is light on the water, no? |

Becky says: "Little Blue Duck," and so it is henceforth |

Second mate, exploring the MARAD Basin, off a bit towards Tongue Point. |

Second mate enjoys the view from the engine box. First time I've seen the big boat from the water, with the boot stripe on. |

A little stern bling, to identify the duck. From Action Signs, easy and quick. |

Hung the dinghy against the shed wall, off the bow eye. |

Bungie on cross-line is insurance. |

Pulleys and cleat a simple system for haulage and tieing it off. |