What the compleat epoxy mixer wears. Respirator mask not shown. Kneepads have been a lifesaver. |

Side plank dry, ready for epoxy. |

Slappin the goo onto frames. All contact surfaces have a couple coats of epoxy. |

This frame is a little light on the filled-epoxy mix. Squeezeout not enough, so more is added after mating. |

Hoisting the panel into position. Two preset drywall screws establish registration for this step. |

Guiding drywall screws into registration holes. |

Lining up drywall screw for registration |

Sinking drywall registraion screw. |

Stern part lineup. Clamped finger tight, then place screws center first, then toward the ends. |

Next day shot of completed fillet. Squeezeout tooled with tongue depressor, then gloved fingers. |

Second side panel now attached. Bottom panels go on after fitting spray rails and chine guards. |

NOTE: Archaic photo: Current versions of frame kit include precut plywood spray rail fillers. | Photo shows one shaped spray rail filler on top of second blank. These fillers were made from laminates. A very poor idea. It would be a LOT easier and quicker to use single boards, or the plywood fillers included in the frame kit. My bad. |

Mounting bolt holes for spray rail fillers. |

Lasering from frame 4 gave waterline locations across the hull. |

Spray rail filler epoxied in position. |

Guard glued and screwed into position -- eighteen feet of gooped-up wood and some two dozen screws! |

Spray rail guard, bow view. Couple placements into plywood pulled, demanding redos. |

Empty frames prior to attachment of bottom planks; twist at bow makes these trickier. |

Aft empty frames; second bottom plank. |

Inside of the plank saturated with epoxy; tipping off the bubbles with a dry foam brush. |

Lots of goop on the frames, for attachment and for fillets. |

Locater pins near the bow align the plank roughly to prevent glue smear. |

Closeup of locating pins. |

Cut off 8 penny nails hold the aft end of the plank off the frames. |

Plank is laid down after support pins are removed. |

Glue on frames; bow section of first bottom plank. |

Completed bow section, first bottom plank. |

Both planks attached. Each one requires 2-3 hours to attach. |

The outfit keeps dust and stray epoxy blobs off the Caped Filleter during fillet smoothing. |

Ass end of the Caped One, enroute to frames at bow end. |

Forming fillet, Frame one. |

Filling all screw placements and discontinuities at panel joints. System Three's QuikFair is amazing! |

Stern view with fairing compound applied. |

Stern after sanding. |

Oblique view after sanding. |

Scraper stage in fairing. A carbide-bladed scraper saves sandpaper and avoids a lot of sanding dust. |

Same section after scraping and sanding. |

Three hours and a quart and a half of epoxy: saturation coat. Squeegee, roll, tip with foam brush. 9 oz mix at a shot. |

Glassing: resin allowed to soak in. Squeegee drawn over glass to remove excess resin, for greatest strength. |

Glass freshly wetted out on bow. |

Stern glass uncured. Mask mandatory when working with this much resin. |

Bow glass cured. Note masking tape under lower edge. |

Razor blade run along tape edge while resin is still green, then excess is pulled up and away. |

Scraping excess resin after two fill coats; saves sanding; best done before full cure. |

Lots of scrapings. Scraping works better than sanding on soft resin. |

First chine guard segment -- aft portion nailed and epoxied on, looking aft. |

Same segment, looking forward. |

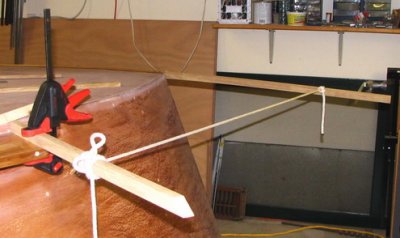

Nails end a few inches before the tail, so it can be planed down some, demanding some creative "clamping." |

Wood brace off ceiling holds the aft end of keel strip in place while the epoxy cures. |

Rear piece of the keel, yucky with epoxy and sitting on screws prior to installation |

Freshly filleted and screwed into position. |

Screwing down the forward portion. |

More fresh fillets, merging keel pieces together. |

Much sanding, filling, and re-sanding later, the boot stripe limit gets masked. |

Five coats of two-part LPU are rolled on and tipped out. Very durable, water-based marine coating. |

Masking removed. Decks and cabin get paint later. Pinstriping will mark the waterline. |

Rear shot after three coats. Each coat took about three hours. |

Time to roll the hull! Castered cradle atop the hull, sitting on sawhorses. |

Strap attachment detail. |

Sawhorses removed as eight helpers lift the hull. An easy lift with this many guys. |

Hull is moved farther back in the garage to allow rolling room. |

Roll begins. |

Almost halfway. |

Half rolled. Cradle made for easy handholds as it came over. |

Three-fourths rolled. |

Roll almost complete. |

Old Guy Chorus: half can't carry the tune ("Barrett's Privateers," Stan Rogers); the other half can't hear! |

ERROR: I removed all the jig cross braces prematurely. Should have left alternate ones in place. | Test fit of starboard tank -- headed for the cutout area below, vent and filler exiting the hull under the deck. |

A couple poor fillets on the keelson/hull line are gouged and sanded to get to solid material. |

Re-filleting those seams. |

Frame 12 is opened for rudder system installation and service. |

A platform for the rudder bearing, formed from the keelson and some added doug fir, topped by ... |

A 3/8th inch plywood cap, to make up enough thickness for a 2 1/4-inch deep rudder bearing, to be installed later. |

Seemed like it would be easier to saturate the exposed wood now, before decks go on. Underdecking will get epoxy as it is laid |

Some fairing to prep for decking; the added frame (6 1/2) was a bit low on top, demanding another quarter inch slice of plywood. |

I used the jig beams for nailers, exploiting the puzzle joints to make a 12-foot piece for each side. This is glueup. |

Starboard nailer. |

Full view. The nailers curve in a very precise way, to fit the ends of the frames. Lots of cool planing |

First set of two filler blocks support stern deck and define coaming curve. Batten aids installation. |

Side view of a filler block. 3/4 inch plywood used in lieu of the thicker fir specified on the plans. |

Filler blocks and stern breasthooks are finished and faired. Fairing these was fun. |

All surfaces decking faired and ready for deck beam installation. |

Deck beams glued in. The set between frames 1 and 2 defines the outsides of the future hatch. |

Bow decking requires care as the panel is aligned onto glue-covered frames, etc. Drywall screws index the sheet, making for a o |

Both bow panels installed. |

Placing ring nails into the nailer demands good aim. Divots represent nail ends ground flush. |

Port panel -- screws on sheer, Ring nails elsewhere, including butt plate at splice. |

Reversed clamps stacked on top of plywood chunks press a rear butt block splice plate in position. |

Last panel in glueup. |

Decking completed, screwholes filled; some fairing and filling to come yet. Hull is now stiff enough to remove jig braces. |

Shaft log prep: 2-7/8 inch hole saw punctures frame 9, over a keelson augmented to support the shaft log casting. |

These Milwaukee 4/6 hole saws cut well -- ran through two bronze screws and kept on truckin'! |

Power boring the first attempt at the shaft hole, with jig board to hold the angle. |

First round failure: guide block split, allowing too much bit runout. |

Shoddy hole filled with epoxy/wood flour; oak/plywood guide block helped the bit run true. |

Most of the boring was done by hand using a socket wrench for better control. |

About an inch in -- guide block solid as an oak. |

Bore is right on the money -- remnant epoxy/wood flour barely visible on the left. |

Auger exits the hull -- right where it needs to be. |

A clean hole and a good guide block. |

Bozo the clown and his eighteen-inch auger. One happy guy |

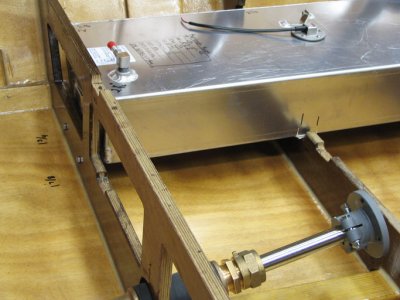

Log and propeller shaft test fitted. |

Log is bedded and permanently installed with 1/4-20 hardware. That 3M 4200 goop is really sticky! |

Rudder pivot also got bedded today, using up the tube of 4200 bedding compound. |

Final lineup for the strut base awaits bearing is installation, and the shaft log bedding cure. |

Hull recess for strut base. |

Temporary installation of strut; ready for the 4200. |

Chafe strips get stuck onto the tank undersides with more 4200. These are made of Trex, that composite decking material. |

Chafe strip closeup. |

Starboard tank, temporarily bolted in position -- easier to fit before the engine logs go in |

Rear of port tank, and shaft. |

Overview of tanks and shaft installation. |

Lamination of one-inch-thick fir boards to make 3 x 3 x 8 ft engine logs. |

Logs after saturation coats of epoxy. |

Port log set low, parallel to the upper sole surface. Notches cut high and worked down using an end-to-end level technique. |

Second log brought in using a cross-level. Satisfying but tedious work, most of it on the knees. |

The frame 6 lag screw holes were placed partially under the top of the frame; hand-twisting bits enlarged holes to 5/16. |

Young Daniel doing some of the heavy lifting. He's OK with a socket wrench ... but not the 4200! |

Both logs bedded and bolted down. They are solid. Really feels good to have a nice home for the engine. |