Acoustic Guitar starting components |

Rope and stick clamps used to clamp the 2 pieces of the top and back together. |

Glueing top and bottom pieces together with wood and rope clamps. |

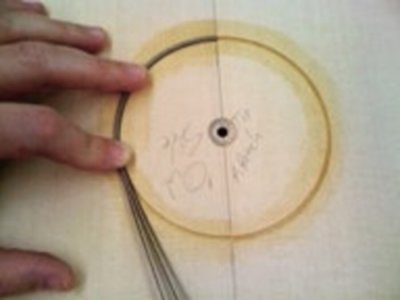

Spruce top glued, sanded to thickness and top traced with location holes for later set-ups. |

The beginning of the sanding process. Maple back sanded from 120, 180 to 220 grit. |

Top cut out with location holes and sound hole located. |

Cutting out the groove for the rosette. |

Rosette pocket cut. |

Inserting rosette. |

Rosette done. |

Cutting the sound hole from the top. |

Cutting sound hole. |

Center brace glued and pockets chiseled out for back braces. |

Back braces glued and clamped into place using "go sticks" to apply even pressure across the brace. |

Back ladder bracing. |

Clamps removed, back braces secured. |

Layout lines for the X bracing, tone bars and wing braces |

X bracing and top braces glued and clamped via go-sticks. |

Other end view of X brace being glued and clamped. |

Tone bars and wing braces glued and clamped. |

Bridge plate and sound hold braces glued and clamped. |

Top bracing completed. All braces and tone bars hand tapered an scalloped. |

Another view of top bracing. |

Side heat press. |

Metal, heat element sandwich. |

Applying pressure to the heated, dampened wood to clamp it into position. |

Closer view of clamp. |

Sides as they come out of the bending press. |

Blocks installed |

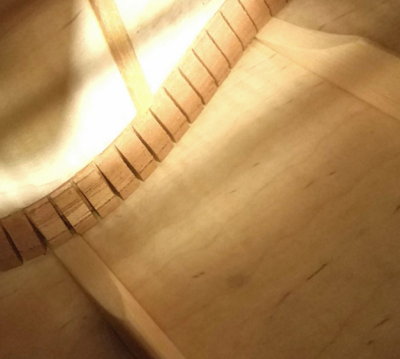

Adding Kerfing to the inside of the body to help support the top and bottom when glued to the side. |

More Kerfing |

Kerfing clamped |

After the clamps are removed. |

Strips glued to inside of body to prevent cracking of the sides. |

Clamped in place. |

Ready for final body height sanding. |

Body in holding jig for sanding and attaching top and bottom to the sides. |

Bottom glued to sides and clamped with go-sticks. |

Top glued on and clamped with go-sticks. |

We have a bird house! |

Top view |

Another view in the sound hole. |

Routering for binding |

Done with first cut. |

Second router cut. |

Ebony fret board blank. |

Body and fretboard blank |

First cut of binding installed. |

Hold down with tape. |

Maple binding and trim to install. (worst part of the build for me) |

Gluing and taping binding |

More tape, more glue |

Binding installed and ready for some heavy sanding. |

Top view of binding |

Edge |

Neck Blank |

Pre cut and ready for final rough cut. |

Routed channel for truss rod. |

Truss rod channel. |

Go stick clamping jig |

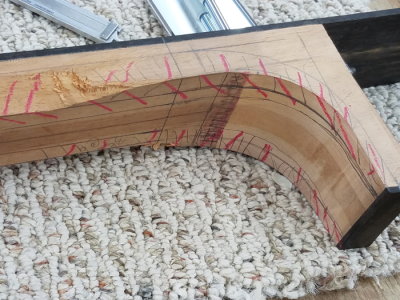

Laying out neck angles for material removal. |

More layout |

Neck layout |

Neck layout |

Neck layout |

Measuring to router out slot for truss rod end. |

Routering truss rod end slot |

Fretboard glued in after truss rod set. |

Mortise cut into body and holes drilled to attach neck |

Tenon cut out of neck |

Ebony faceplate glued to headstock. |

Starting to look like a guitar. |

Reverse angle |

Sanding final fit of ebony and mahogany |

Neck to body fit |

Slip sanding neck for perfect, seamless fit. |

Laying out neck |

Drilling tuning machine holes |

Headstock drilled for tuning machines |

Initial neck contour layout for chisel |

Layout |

Layout |

Neck holding jig |

First cut removal |

Taking shape |

More layout |

Again |

Rasp and file neck |

Rasp and file neck |

Another neck layout after removing the first cut |

More layout for removal |

Carving valute |

Getting close |

90% there |

Headstock inlay layout |

Fretboard jig |

Headstock to valute to neck |

Neck to heal |

Leveling and contouring fretboard |

Straight, radiused and polished fretboard |

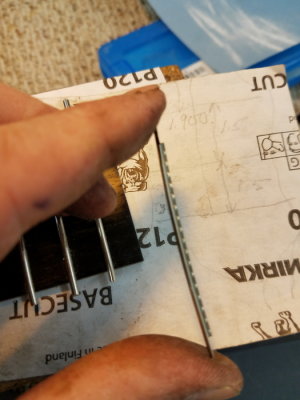

Cutting tang in frets |

Installing frets |

Fretboard done. Radius, leveled and frets installed filed and beveled. |

Inlay glued in. |

Inlay finished. |

After a long busy day... |

Back sanded |

Top sanded |

Electric Guitar, sunburst finish with 16 c.oats of Lacquer |

14 coats of clear lacquer on my hand I used to hold the body while spraying . |

Final wet sand of electric. 800, 1000, and finally 1200 grit sandpaper |

Spraying acoustic |

6 coats of lacquer (many more to come) |

Acoustic neck sprayed |

Acoustic neck |

Acoustic back |

Front again after first 6 coats |

Meanwhile, back to the electric |

Body and neck assembled back together |

Fitting the nut blank |

Spacing strings |

Arrached bridge |

Nut slots cut and top taken down to proper height. |

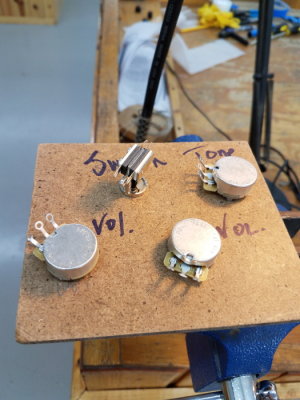

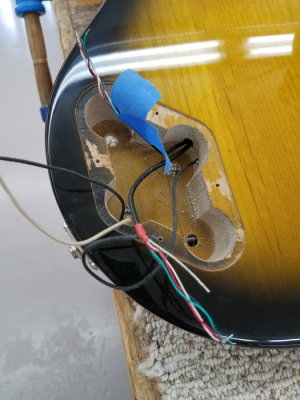

Switch, tone and volume pots attached to soldering board |

Pots and switched soldered together |

Pick up wires and end pin jack wires soldered and pulled into back pocket |

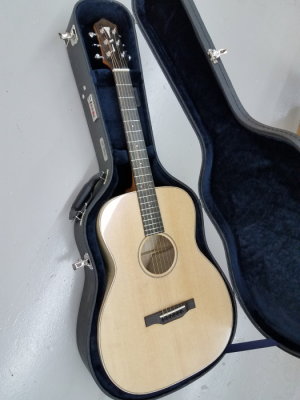

New cases have arrived! |

electronics tested and working! |

Final neck set, bridge set for proper string height, radius and intonation. |

Done and polished body top |

Back |

Nut polished |

Finished, in case awaiting final grade. |

Frets installed in acoustic |

Fretboard |

Body sanded to 1200 ready for buffing |

Buffing |

Neck body fit after 4 hours of slip sanding |

Neck bolts coundtersunk |

Fretboard glued to top after lacquer was removed |

Neck set |

Neck set |

Bridge finished (blank of left is what we started with) |

Frets leveled, crowned, sanded and polished. |

Lacquer removal using router jig |

Lacquer removal using router jig |

Lacquer removal using router jig |

Bridge clamp "dry run" |

Dry run |

Bridge glued, clamped with plenty of run out. |

Bridge clamped |

Today's goal was to get everyones bridges clamped to dry overnight. |

Bridge pin holes drilled though body and countersunk. |

Grooving bridge pin holes to allow for string using solid bridge pins. |

String groove cut for Low E string. |

Bone saddle fit and finished to length and width. |

Rough height cut |

Bone nut cut and fit to width and length |

Top view |

String slots spaced and measured |

Done for the week, next week finish saddle, nut and set up, sand buff and polish everything and it will be done! |

The electric is now home with its new friends.. |

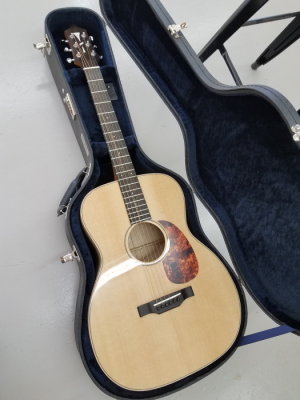

Acoustic finished for grading. (pick guard removed after grading) |

Top |

Nice stripe in ebony fretboard. Frets polished. |

Solid maple sides and binding |

Gotoh Tuning machines |

Headstock |

Solid Maple Back |

Bottom, tapered ebony end pin. |

Top without pick guard |

Soundhole, fretboard |

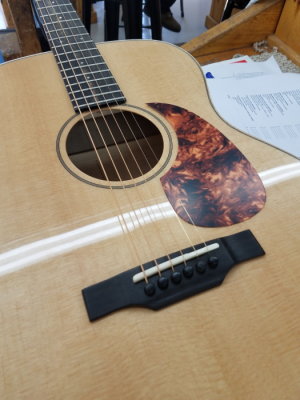

Final saddle and bridge |

Finished rosette |

Ebony fret board |

neck to body fit |

Maple side and binding |

scalloped braces |

Bridge and saddle |

Valute |

Graduation |

Home sweet home. |