|

|

|

|

|

|

| Rolf | profile | all galleries >> Galleries >> DIY Toner Transfer Paper & Techniques for making PCB,s | tree view | thumbnails | slideshow |

DIY Toner release agent and applicator |

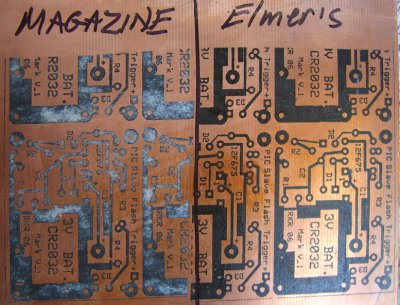

My Elmer's Home made transfer paper test. |

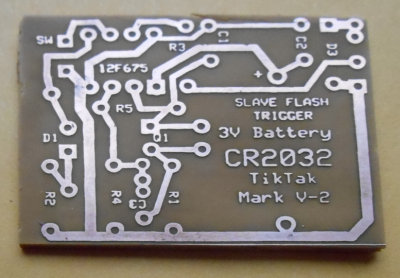

Toner Transfer DIY PCB |

| comment | share |