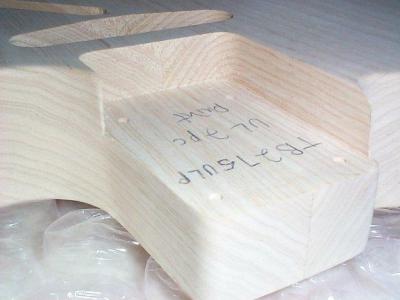

50's style 2 piece ash body from MusiKraft in Sicklerville, NJ |

I started this project intending to just replace another body for this one. |

The holes for the string ferruls did not come countersunk |

I like the squared off edges and edge radius similar to early Fenders |

This body was considered paint grade and therefore only cost about a $100 |

The bridge mounting holes were tapped but not drilled (as were the neck) |

Note my super clean work area. |

To get the proper shade of filler for the ash I mix light with natural |

The filler is applied into the grain and the excess wiped off |

I'll clean the ferrul holes out later |

It will hang to dry overnight |

At this stage neatness is not a big concern |

The next day I've taken it outside to sand the excess filler off |

I'll remove the filler from the surface leaving the pores and grain filled |

A sanding block helps keep the surface flat |

A vibrating sander speeds things up |

I'm now ready to apply a lacquer sanding sealer. |

Brushed on it will hang to dry overnight |

Back outside again to sand off the sealer from the surface |

Nearly messed it up trying to rub on a tint coat (I also added the channel to the neck) |

The lacquer is strong so will hang in the garage overnight |

Using a foam brush I was able to tint it a little more consistently |

I now begin to spray several coats of clear nitro cellulose lacquer |

It helps doing this in the sunlight lacking a proper booth |

a couple of coats, sanding in between and I let it harden overnight |

Back outside for a few more coats |

A lot of the coats will come off during the wetsanding process |

That's about it for spraying |

I used a Sherwin Williams lacquer and and amber tint |

after drying overnight outside its back in the cellar for a week |

A week or 2 (I forget) to cure and I'm ready for sanding |

Different grades will be used to smooth the finish |

The bucket of water is there to keep the paper clean and wet |

I do the top, back and then the sides |

After the sanding comes the rubbing compound |

Its pretty much the same as automobile finishing |

Lots of elbow grease |

Well, we got a body. Might as well finish it. |

I most of the other parts (Fender) from Smart Parts (the pickguard will go back) |

A freind had a tool that allowed us to counter sik the ferrul holes very accurately |

I had to mod the pickup cavity a litlle to get things to line up |

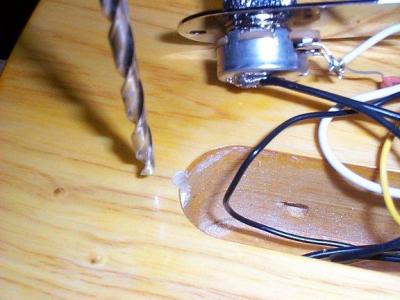

I drill a hole to run a bridge ground before installing the bridge |

I chose a vintage 3 saddle bridge with the Fender Noiseless pickups |

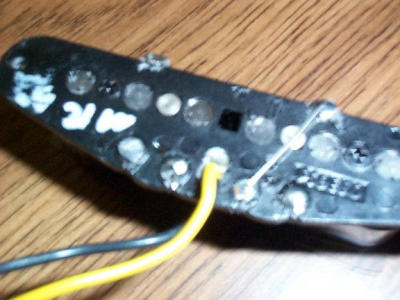

I begin to assenble the control plate but am awaiting a 4-way switch |

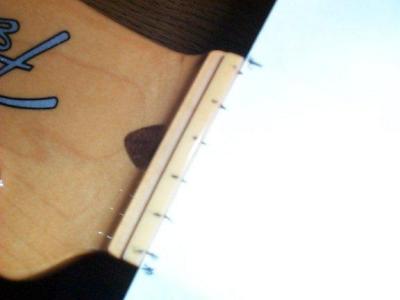

I got a Fender 50's MIM neck on ebay (this saved a lot of work) |

The neck came finished, with a serial number and tuner screw holes drilled |

There is even a logo from the factory |

After drilling neck holes I soap the neck screws for easier installation |

The neck also came with a Fender neck plate and nickel plated screws (not slotted though) |

The necks on. The channel aids in truss rod access |

Getting there. |

I had some strap buttons, the locking kind (but no locks) |

They'll do fine |

The rest of the parts are here |

The drill press comes in handy pressing the tuner bushings in |

The Vintage style tuners just screw on (slotted) |

With the VN pickup I found it necessary to dig out the the cavity a bit |

The ground strap will be removed and a third wire soldered as per 4-way switch spec. |

The only non fender component is the RS ceramic .047 cap |

All soldered up and nowhere to go (4 way switch and a No-load tone pot) |

I've don't want to mount the controls without the pickguard |

The guard was on special order, but I cancelled and bought a 52 RI instead |

As I thought, the control cavity is too far back |

I will have to mod the cavity to mount the plate |

I drill a hole with the press out of the ledge of the cavity |

I then glue a piece of dowel in to build up the ledge |

Using another guitar as a template I've marked the slot positions on the nut |

I start by cutting slots with a razor saw |

I use aneedle file set for the thicker string guages |

I now have rough cut the nut |

with strings installed I fine cut the nut slot depth |

Protecting the finish I intonate it |

From the back its complete |

After finishing it, I loaned it to a studio for a couple of weeks and then 6 months later sold it. |