|

|

|

|

|

|

| Jim Thode | profile | all galleries >> Crosscut Saws >> Inverse Crosscut Saw Filing / Sharpening | tree view | thumbnails | slideshow |

Cutter Detail |

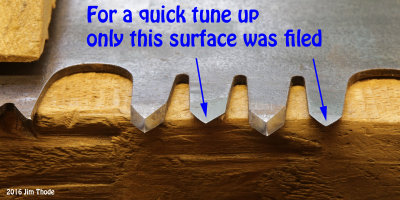

Filing Cutter back side |

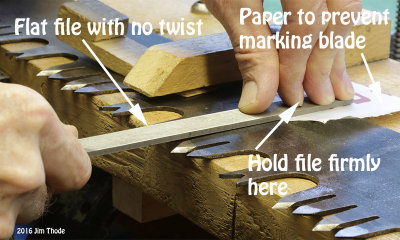

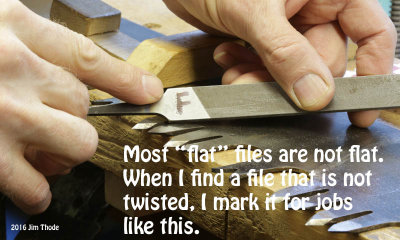

Flat File |

Straight edge on saw |

Testing |

Testing |

:: Flat Tip Filing :: |

| comment | share |