|

|

|

|

|

|

| fred harmon | profile | all galleries >> Galleries >> tirechange | tree view | thumbnails | slideshow |

Mark Parnes Balancer http://www.marcparnes.com/ |

Marc Parnes Balancer |

Marc Parnes Balancer |

MoJo Lever |

I used these female drop in threaded anchors to secure the stand |

The bolt drives a plug in the bottom that expands the anchor |

I capped each anchor when not in use with a short bolt to keep out dirt |

I installed the anchors on three corners for the stand, in an out of the way location on my patio |

Heating the new tire in the sun makes it easier to mount |

Harbor freight tire changer stand (model 34542) and motorcyle adapter (model 42927), motion pro tire iron, and rim savers |

The bead breaker works real nice. |

Here you can see the clamps used by the tire changing stand. They came installed backwards, I had to turn them around. |

I covered the clamps with rags to protect the rim |

Rim installed on clamps |

Wheel in stand, ready to begin |

Tire iron and rim saver in action. |

Here I have the first side of the old tire almost off |

Use the flat end of the tool to remove the old tire from the rim. Go clockwise. Notice upper arm of stand has been removed |

This shows the second side of the old tire coming off. Notice I am using the long tire tool. |

Using the flat end of the tool to remove the old tire. It is easier to work on the tire with the upper arm removed from stand |

Old tire coming off |

Half way done! |

I clean the bead area with mineral spirits to get the tire residue off and to insure a good seal. Your dealer doesn't do this. |

I use regular ole silicone spray to lube the tire for installation |

Rim savers in place and the first side of the tire being started with standard tire irons |

Tire being started on rim |

Here the first side goes on, with minimal problems. |

I used the Harbor Freight tire tool to install the first side. I gave up on the rim savers. |

Only one side left to go. |

I cut a rim saver and melted slots in it & zip tied it to the mounting tool. This prevents the rim from getting sctatched. |

I formed a piece of high density plastic around the removal end of the tool |

I formed a piece of high density plastic around the removal end of the too |

Here I re-lube the bead area before attempting the final side. |

Now I position the long tool in place with the bead breaker over the lip of the rim |

Next I get the edge of the tire started and use a tire iron to hold on position |

Now that my rim saver that is attached to the tool slides on the rim, and protects it |

This is a trick I learned to keep the mounted portion of the bead in the valley of the rim |

Keep working around slowly, and add more silicone spray if you need to |

Continue using the tool in a clockwise direction to work the bead on. Use blocks to hold the bead in the valley of the rim |

Lift the tool occasionally to force the bead over onto the rim |

Once I figured out the tricks, it went on just fine. |

This is my home made balancer. It uses roller blade bearings. |

I made an axle out of a piece of pipe to hold the rear tire on the balancer |

The heavy spot rotates to the bottom. Add weight till it balances. Easy as pie. |

Checking the clearance on the brake caliper holder. |

MoJo Lever |

MoJo Lever |

MoJo Lever |

MoJo Lever |

Wheel 002a.JPG |

Wheel 004a.JPG |

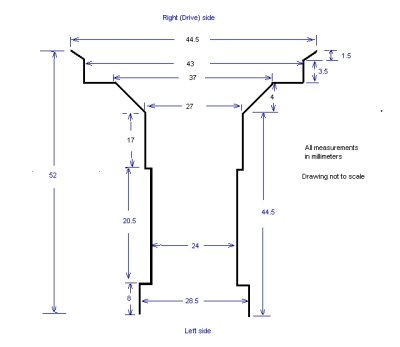

WheelDimensions.bmp |

Tire iron used to pry bead over rim to prevent bending MoJo bar end |

Mojo taking off first bead |

Mojo mounting first bead |

MoJo bar mounting Dunlop |

MoJo bar in action mounting Dunlop on GoldWing wheel |

New stronger bolt removing second bead on GL1800 |

New stronger bolt removing second bead on GL1800 |

MoJo Blocks rim protectors |

Drilling the hole to install MoJo block |

I had to use needle nose pliers to reach in and hold the nut while I tightened the allen bolt |

MoJo Blocks installed |

TireBalance 003a.JPG |

TireBalance 005a.JPG |

DunlopE3_MT 001a.JPG |

DunlopE3_MT 003a.JPG |

DunlopE3_MT 005a.JPG |