First, jack the bike just enough that the front wheel is off the ground |

Now remove the instrument panel cover. Take out the bolts and push rivets under the speaker grills |

Lift up on the bottom of the panel to remove |

Push out on the tab on the electical connection under the panel and dissconnect the connector |

Here you can see the connector after the panel is removed. |

Here is the other side of the connector on the bottom of the instrument cover panel |

Remove the screws holding the fork cover on. |

Pull out the black plastic fork end cap cover |

Lift up on the rubber cover for the stem nut and turn signal cancelling unit |

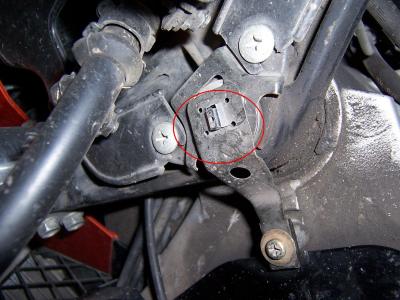

Pull out the turn signal canceling circuits connector |

Disconnect the connector and push aside |

Remove the 30 mm stem nut. A large crescent wrench or pliers (if you're desperate like me) will work, a 30mm socket works better |

Remove the stem lock nut |

Now, loosen the upper triple clamp bolts. A 12mm socket and ratchet is used here on the left triple clamp. |

Here I am using a box end 12mm to loosen the right side triple clamp bolt. |

Take note of how the cables and hoses are routed so you can get them back in their homes when you are done |

Here is a look at the cables & hoses on the left side |

Now remove the bolts that hold the bars on the top bridge |

Use a cloth to protect the bike and carefully lay the bar to the side |

Do the same with the other side. |

Now remove the cables support clamp |

pull the clamp free, being careful to note which hoses went where, and how the clamp was oriented (throttle cable UNDER bridge) |

Loosen the top triple tree clamps for the forks on the top bridge |

Rock the top bridge back and forth to free it, then maneuver it out the top |

Here is a look at the top bridge after removal |

Now you have good access to adjust the bearings using the Honda Tool. Torque to 20ft/lbs |

This lockwasher has two prongs that point up onto the locknut and two that are bent down onto the adjuster nut. |

This is my home made tool for adjusting the bearings. Honda sells a prettier one for $45 |

This page shows how to re-pack the upper and lower bearings with grease |

Here is the top race being removed |

Here is the top bearing being removed |

Here is the stem with the bearing and race removed. The front wheel has to be chocked and on the ground, or the stem will drop |

This is the top bearing and the top bearing outer race |

Here are the top bearing components removed |

I put on lots of high quality synthetic moly grease on the bearings |

Bearing and top race loaded up with grease and ready to install |

Note front wheel is chocked to hold bottom of steering stem in place |

Here I have the top bearing removed, turn signal cancel arm dissconnected, and the stem slid down to expose lower bearing |

Here is another view of bottom bearing. Notice it is dry and needs to be greased. I greased it and pushed the stem back up |

Here is the upper bearing greased and re-installed |

Once in place, I filled the void with grease and really packed it in |

Now I re-install the seal. |

I lubed the bearing adjustment nut with oil so I could get a nice 20 ft lb torque on it |

Bearing nut re-installed and ready to be torqued to 20 ft lbs |

Here is the turn signal cancel unit removed from the bike |

The tab on the bottom of the cancel unit gets pushed onto the wiper arm |

DriverTool.JPG |

DriverTool2.JPG |

DriverTool3.JPG |