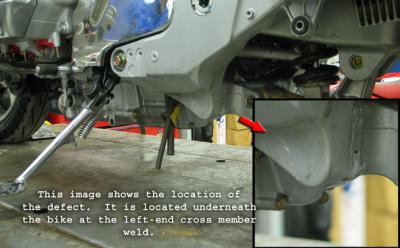

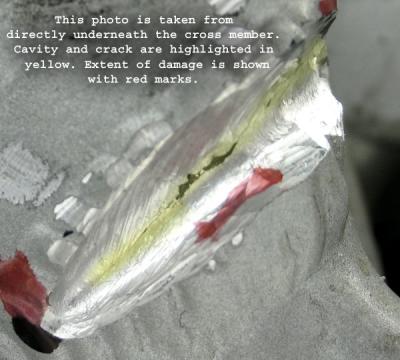

This is the newest location cracks have been found in. Inspect both left and right sides and all the way around and under |

Burn through on reweld Bike U |

Burn through on reweld Bike U |

Right weld of bike Z rewelded at the factory in Marysville Ohio |

Right weld of bike Z rewelded at the factory in Marysville Ohio |

Left weld of Bike Z that was rewelded at the factory in Marysville Ohio |

This bike was rewelded in the UK at a centralized facility Left side (Bike P) |

UK reweld right side (Bike P) |

Prior to fix Bike G |

After fix Bike G |

Prior to fix Bike G |

After fix Bike G |

Bike 1 Before Weld Left Front |

Bike 1 After Weld Left front |

Bike 1 Before Weld Left Rear |

Bike 1 After Weld Left Rear |

Bike 1 Before Weld Right Front |

Bike 1 After Weld Right Front |

Bike 1 Before Weld Right rear |

Bike 1 After Weld Right Rear |

This is yet another frame after reweld Notice large bead in center!(Bike C) |

Here is a look at a crack frame discovered during the re-weld process.(Bike A) |

Honda is refusing to replace this bike and/or frame and is only offering to attempt to re-weld it. (Bike A) |

Here is a look at another frame after grinding (Bike B) |

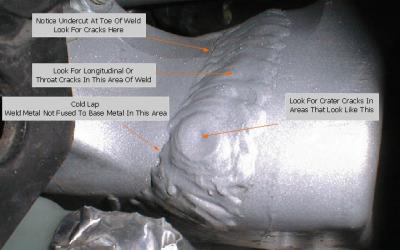

This is a typical weld found on a GL1800. Notice poor quality of weld |

Welds on a brand new 2004 |

Welds on a brand new 2004 |

Welds on a brand new 2004 |

Welds on a brand new 2004 |

FJR 1300 weld (for comparison) |

FJR 1300 weld (for comparison) |

This 2001 belongs to an Iron Butt rider and has been to Alaska. I inspected the entire frame and it is crack free |

Reweld photos. Build date 07-02 |

Reweld photos. Build date 07-02 |

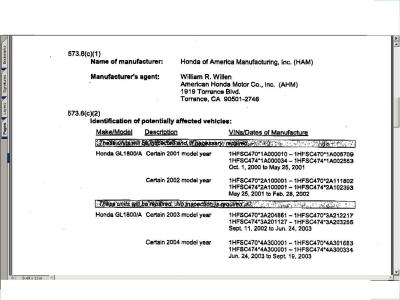

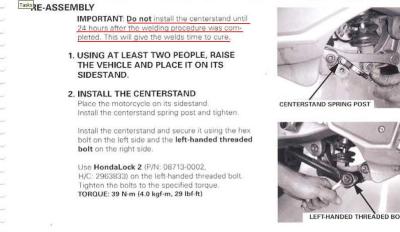

recall doc |

Cure time required is 24 hours after welding |

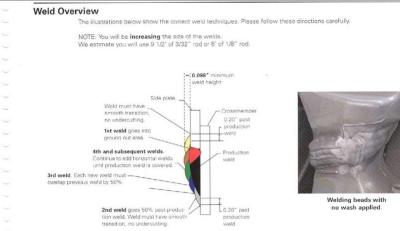

Welding instructions |

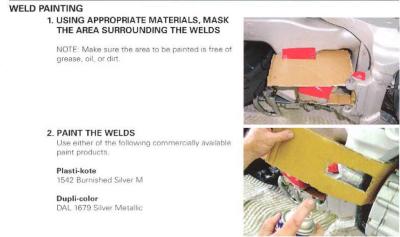

Painting |