Bike jacked and front fender and caliper covers removed |

Removing the lower left brake caliper bolt with an allen socket bit |

You need a torx bit to remove the upper bolt on the left brake caliper |

Torx socket used to remove left caliper. |

I used a bungee to tie support the caliper once removed. |

Removing right caliper with 12mm socket. |

Removing the axle bolt. |

Loosening axle clamp bolts. Notice caliper is supported with bungee to reduce stress on brake lines. |

Remove the axle, then just roll the wheel out. |

a 6mm allen wrench is sacrificed. I cut it so it was long enough to reach the bottom bolt through the bottom of the fork leg. |

I then put the allen into a 6m socket and ratchet to hold it. |

Now I use my newly made tool to remove the bottom bolts. |

bottom bolts and copper sealing washers. |

and out comes the oil |

Here I loosen the left top triple tree clamp. |

Next I remove the left top cap. |

After pulling out the spacer, I fished the spring and washer out with a plastic coated coat hanger. |

Spring and washer are removed. |

Right side fork cap removed and locknut underneath loosened with a 14mm open end wrench |

spacer, washer and spring come out. Be carefull not to drop the washer down the Honda Hole. |

Right side damper assy simply lifts out. You do not need to remove the left damper, as it doesn't retain fluid anyway. |

Here I have removed the right damper and am pumping all the old oil out of it. Notice oil drained into measurment containers. |

Re-install damper rod once fully drained, and with springs still removed, reinstall and tourque bottom bolts. |

Pour in new SS-8 10w Honda (Showa) fork oil. 529 cc's left, 485 cc's right. I purposley overfilled and then removed the excees. |

First pump both fork legs a dozen or so times to get all the air out, then support them fully compressed. |

now pump the right damper rod several times to bleed and re-fill the damper with the new oil. |

Continue to pump the rod until you are sure you have all the air out. |

Mity Vac tool set to 5 inches (128mm) per the manual |

Mity Vac tool with homemade alluminum rod and rubber tip and stop block used to set fork oil level |

With forks compressed, and springs removed insert the rod to the stop block and draw out the excess oil. Now it is set perfecly. |

Reinstall the springs, washers, and spacers and top caps and front wheel. Your done! |

Progressive Springs. Notice I got a set that is not matched in length. |

Here is another angle look at them |

Here is a photo of my last moonshot |

LeftForkLeak.JPG |

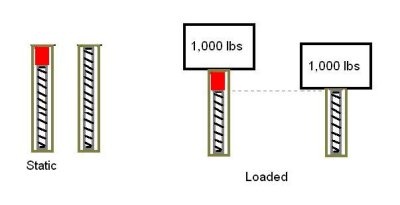

preload.JPG |

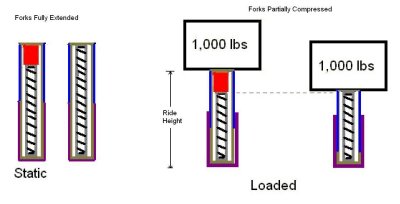

preload2.JPG |

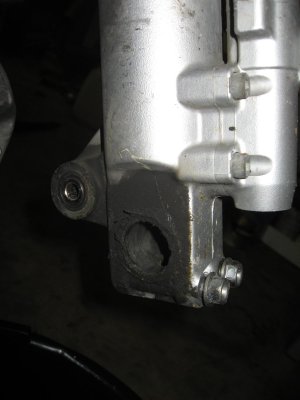

BottomValve 001.jpg |

BottomValve 002.jpg |

BottomValve 003.jpg |

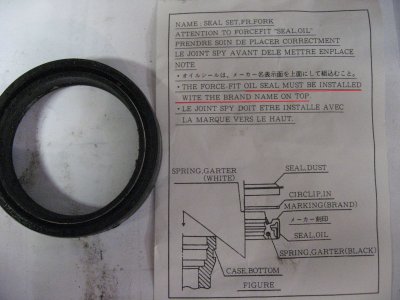

GL1800ForkSeal 001.JPG |

OldForkSeal.jpg |

ForkSealGrease.jpg |

LeftForkSealLeak.jpg |