Windsheild in up position. System provides three inches total travel |

Windsheild in down position |

Windsheild in down position |

Windsheild in up position |

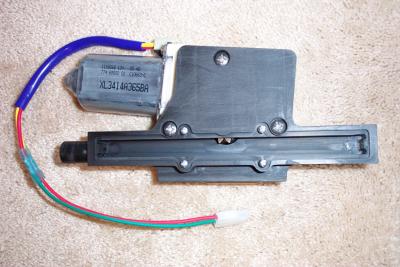

Here is the contents of the actuator kit |

This is a look at the underside of the actuator motor and drive |

Here is the other side of the actuator |

I weighed the entire contents at just under 4 pounds |

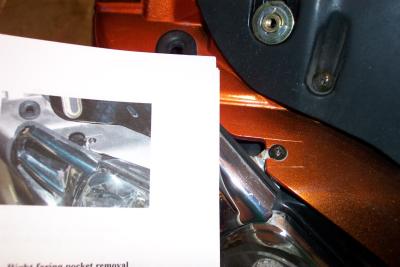

The new right side pocket looses some space |

New pocket and old pocket side by side |

Controller switch mounts on handlebar |

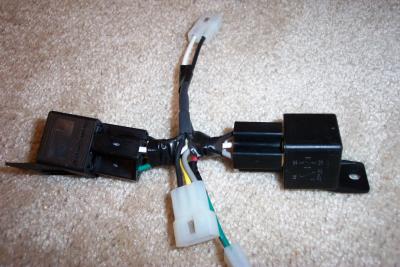

Relay harness has quality connectors on it so it all just plugs together |

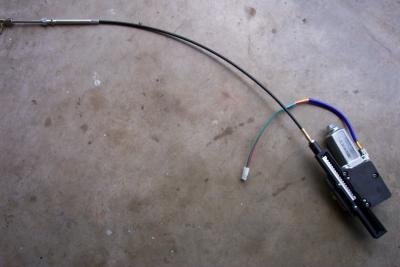

Actuator cable |

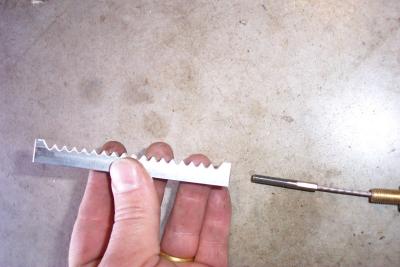

Rack drive simply screws onto the end of the cable |

Rack drive unscrewd from cable end |

Rack is inserted into the actuator |

It should be inserted at the mid point of travel |

The cable end then is screwed into the end |

Rack attached to cable end |

Assembled actuator |

Preparing to enlarge hole for cable |

Hole size marked |

A dremel tool makes short work of the plastic |

The cable then is threaded down into this newly made hole |

Cable pushed through |

Replace the lock nut after you thread the cable into place |

Next, thread the cable end into the actuator housing |

Now screw on the rack drive |

Liberally grease the gears and rack |

Insert it at the mid point of travel |

Install the cover for the drive |

Screw the cover into place |

I used a zip tie to loosly hold the motor to the fairing support |

I pushed the relays up into the space between the fairing and the actuator on the right side |

Electrical connections are made directly to the battery (black and white wires) |

Actuator in place. The extra wires hanging out are for my Ipod, and have nothing to do with the actuator |

Actuator positioned under pocket |

Actuator positioned under pocket |

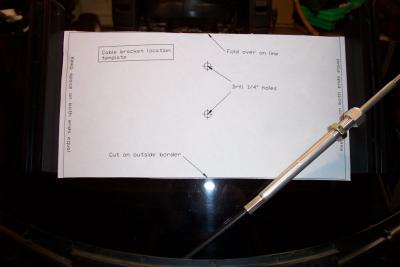

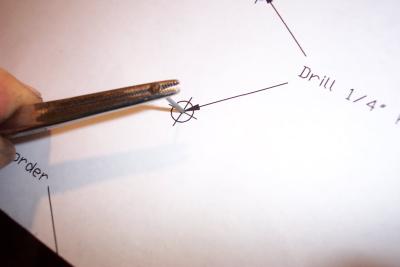

Cut out the template for the windshield |

I used a hot nail to mark the spot where I wanted to drill |