Checking pads with wheel installed. Lay down and look up at the bottom of the calipers |

You can see the top side by looking down in through the fender with a light |

First I removed the fender and wheel |

I left the caliper bolts threaded in enough to hold the caliper |

Then I removed the bolts on the rear of the caliper |

You don't have to remove the back just to replace the pads, but it makes cleaning the pistons easier. |

Now I remove the plug over the brake pad pin bolt |

And then I remove the bolt |

When you pull the pin bolt out, be ready for the pads to fall out. |

Now I carefully clean the pistons with a toothbrush and soapy water to get all the grunge off. |

Then I blow it dry with compressed air to make sure all the soap and grit is gone |

I follow this up with a bit of de-natured alcohol |

Now I can push the pistons back in with my thumbs |

Here you can see my old pads are down to 2mm. They could still be used for a while longer, but at 1mm they should be replaced |

Here is a comparison to the new pads, which are just over 4mm |

4mm on the new pads |

Left and Right side front pads |

Wear indicators are at about 1mm |

Wear indicators are at about 1mm |

Here is a look at the back half of the caliper with anti-rattle spring. Note the irregular edge faces out. |

Here is a look at the anti-rattle spring. |

You can feel how the caliper moves on the slides by pushing on the black portion with the wheel removed |

Here is a look at the upper left slide. This needs to be greased |

Here is a better look at the slide under the rubber boot |

Here is a look at the lower left slide. |

I carefully smeared some high temp grease into the boot and on the slider |

The right side brake slides are easier to get at, as you can remove the whole caliper, and expose the slides. |

Here is another look at the right side caliper slides |

I smear High Temp grease on both slide bars. |

Here I get the other slide. |

I also grease the bushing on the left caliper for the anti-dive system |

Here I use brake cleaner to clean the rotors |

Here is a look at how the top of the pads are held in |

See how both pads fit into the retainer clip. |

Here is a look at how the pad is held in both top and bottom |

There is a small o-ring on the end of the pad pin |

To install the new pads, I first install the pin into the pads and let them hang. |

Now I align the inboard pad with the left edge of the caliper bracket and push it up into place. |

Once it is up all the way, you have to slide the caliper bracet back to get the top notch in the pad into the retainer |

Here the pad is fully inserted and the top notch is in the retainer |

Inboard left side pad installed and caliper shifted over to facilitate installing outboard pad |

Do the outboard pad the same way. |

This gave me a good opotunity to clean the forks lowers and fender inside real good. |

Tweaking Rotor Carrier on a Kawasaki Concours |

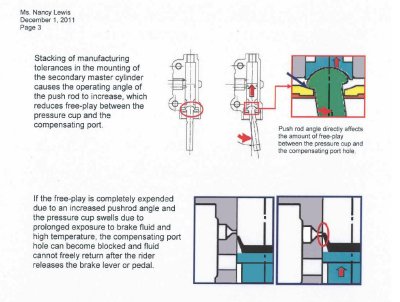

SecondaryBrakeClevis 001a.JPG |

SecondaryBrakeClevis 002a.JPG |

GL1800BrakeRecall.JPG |

The left inboard pad always wears out first on the GL1800 |

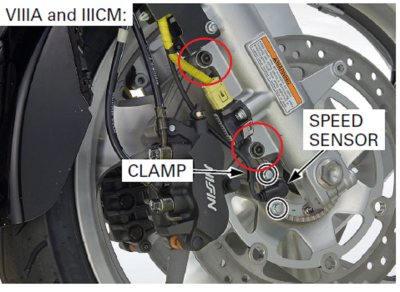

AirBagLeftSide.jpg |

AirBagRightBrake.png |

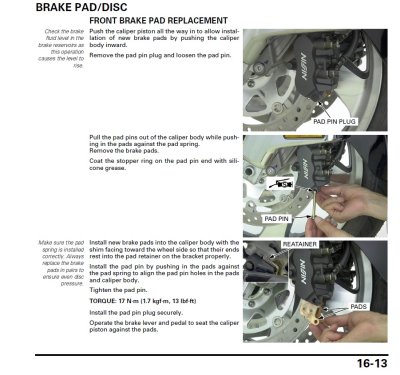

PadReplace.jpg |